PRODUCTS

SiC Coating Specialist

-

Properties of SiC

-

Physical properties

Thermal Conductivity(W/mK) 190 Poissons Ratio 0.17 Bending Strength(MPa) >240 Compressive Strength(MPa) 1600 Purity(%) >99.9(CVD>6N) Bulk Density(g/cm*) >2.93 Youngs Modulus(GPa) 340 Load0.5Kg HV1=9.807N Vickers Hardness(GPa) 22 Thermal Expansion(x10-6/℃) 25~400℃:3.8

25~800℃:4.6volume Resistivity(Ω . ㎝) 10-1 Specific Heat([PT]J/Kg.K) 0.7

-

-

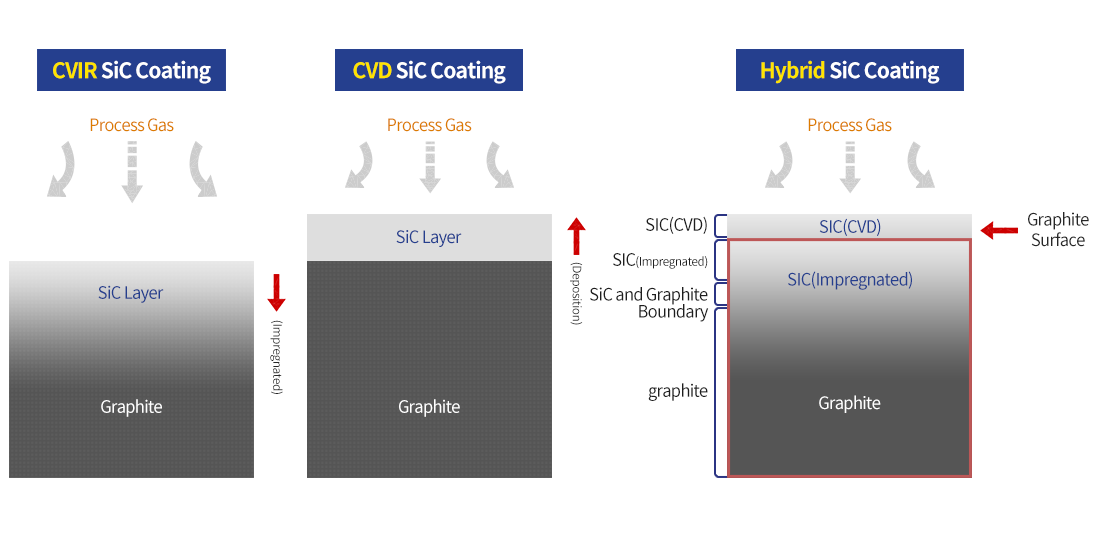

POSSESS THCHNOLOGY PROCESSSiC Coating Technology

- - (Tech 1. – CVIR ): SiC layer located inside of graphite

- - (Tech 2. – CVD ): SiC layer located on the graphite

- - (Tech 3. – Hybrid ): Complexed SiC layer located inside and on the graphite

-

Strong Point

-

Cost

- - All of graphite can be coated by SiC

-

Productivity

- - No need post-machining to meet high precision

- - More Short coating time

-

Diversity

- - Here are many various material can be coated by SiC (Graphite, Carbon-Carbon Composite, RBSiC,…)

- - Complex parts can be coated by SiC

-

-

Applications

-

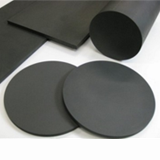

Wafer Carrier(susceptor)

-

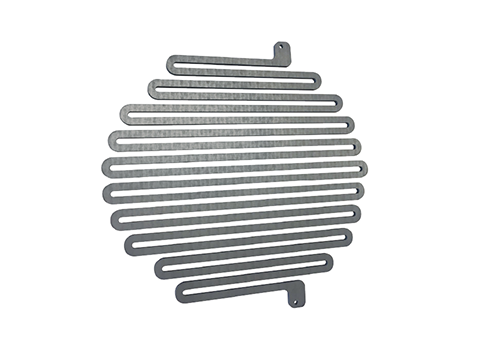

High precision graphite heater

-

SEMICON graphite parts

-

Carbon Composite

-

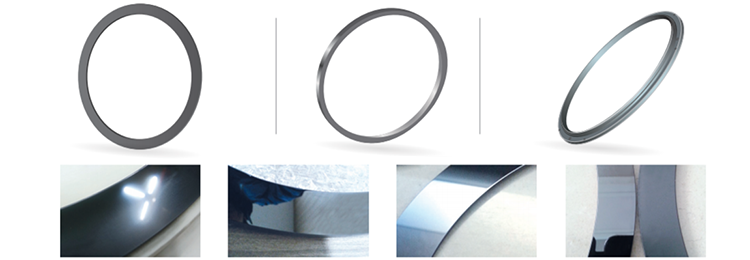

SEMICON SiC Ring

-

-

PROCESS

STEP 01

Preparing Graphite (Japan Graphite)

STEP 02

Machining

STEP 03

High purification

STEP 04

SiC Coating

STEP 05

3D Measure

STEP 06

Packing